Maximizing Concrete Waterstop Performance with Rubber Solutions

Concrete waterstops are an important component in construction projects and are used to prevent water from passing through the joints of concrete structures. These waterstops are critical to maintaining the integrity and durability of concrete, especially in areas prone to water exposure. In order to improve the performance of concrete waterstops, the use of rubber waterstops is becoming more and more common. Concrete rubber waterstops offer a range of benefits that can significantly increase the effectiveness of your waterstop system.

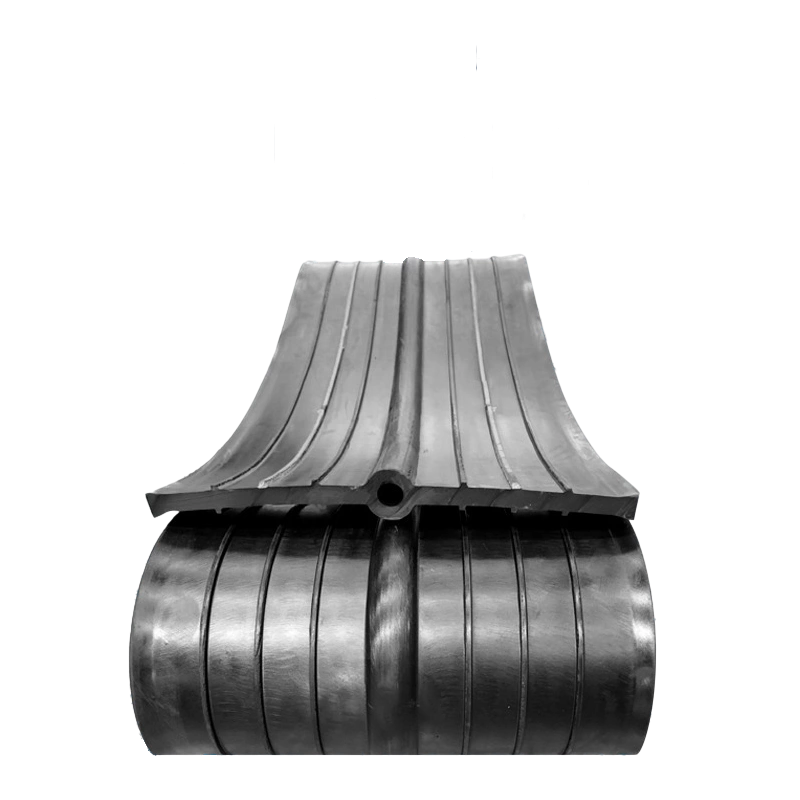

Rubber waterstops are designed to provide a reliable and durable barrier to water penetration in concrete structures. They are made of high-quality rubber material that offers excellent elasticity, flexibility, and water and chemical resistance. When rubber waterstops are integrated into concrete joints, they can effectively seal the gaps and prevent water from seeping in, thereby improving the overall performance of the waterstop system.

One of the main advantages of using rubber waterstops for concrete is their ability to accommodate joint movement. Concrete structures are subject to various forces and movements, such as expansion, contraction and settlement, which can cause stress on joints. Rubber waterstops are engineered to withstand these movements without compromising their sealing capabilities. This flexibility ensures the waterstop remains intact and functional even under dynamic and challenging conditions, maximizing its performance and longevity.

In addition, rubber waterstops have excellent resistance to aging and deterioration. The inherent properties of rubber, including its elasticity and weather resistance, allow waterstops to maintain their sealing integrity over the long term. This resistance to degradation ensures that the waterstop continues to provide effective waterproofing protection even in harsh environmental conditions. Therefore, the use of rubber waterstops contributes to the long-term durability and sustainability of concrete structures.

In addition to their functional benefits, rubber waterstops are easy to install and customize. They can be customized to meet specific project requirements, including different joint sizes, shapes and configurations. This versatility can be seamlessly integrated into a variety of specific applications, ensuring a precise and secure fit. Additionally, the installation process is simple, saving time and labor costs while ensuring a reliable and efficient water stop solution.

Using rubber waterstops for concrete is also consistent with sustainable building practices. By improving the performance and longevity of water-stopping systems, rubber solutions help improve the overall resilience and durability of concrete structures. This in turn reduces the need for maintenance and repairs, minimizing the environmental impact associated with construction activities. Additionally, the durability of rubber waterstops supports the long-term integrity of concrete, promoting sustainable infrastructure development.

In summary, the use of rubber waterstops for concrete offers several advantages for maximizing waterstop performance. Rubber waterstop’s flexibility, durability, resistance to aging and ease of installation make it ideal for effectively sealing concrete joints and preventing water penetration. By incorporating rubber solutions into water-stopping systems, construction professionals can improve the durability, sustainability and overall performance of concrete structures, ensuring long-lasting waterproofing. As the construction industry continues to prioritize quality and longevity, the adoption of rubber waterstops represents a valuable strategy for achieving reliable and resilient concrete waterproofing solutions.