- Home

- News

- Don’t choose the wrong engineering waterproof material! There is such a big difference between the water stop strip and the water stop belt.

Don’t choose the wrong engineering waterproof material! There is such a big difference between the water stop strip and the water stop belt.

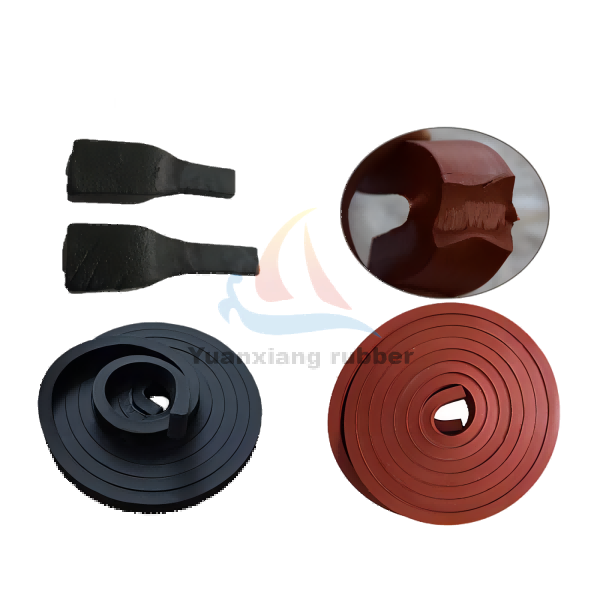

In engineering and building construction, waterproofing has always been a very important section. In different places, the waterproof materials and waterproof processes used are very different. Water-stop strips and water-stop strips are commonly used engineering waterproof materials in engineering construction. There is a difference in one word, but these are two very different materials. Recently, many friends confuse the two engineering materials of water stop strips and water stop belts. In addition, they are all long strips, which makes it even more difficult to distinguish. However, water-stop strips and water-stop belts are two different waterproof materials, and they are different in water-stop principles, scope of application, construction methods, and their respective advantages and disadvantages.

1. The water-stopping principle of the water-stop strip and the water-stop belt are different

The water-stop strip expands after absorbing water to fill the gap between it and the concrete to achieve the effect of water-stopping. Therefore, its composition materials include expansion materials, in addition to rubber and additives. It is a kind of Self-adhesive waterproof material in the form of rectangular strips. The waterstop is a belt to prevent and prevent water from penetrating.

2. The scope of application of the water stop strip and the water stop belt is different

Waterstop strips are generally used in non-essentially important parts of buildings or parts with less strict requirements, such as underground buildings without water, basement exterior walls, etc., mainly to prevent capillary water in the soil layer, so the surface is covered with soil or planted Soil underground garage roof is not applicable. Waterstops are generally used for vertical waterstops in waterproof parts, such as settlement joints, expansion joints and other places with large settlement and deformation. When using them, other aspects of the building should be considered.

3. The construction methods of the water stop strip and the water stop belt are different

When the waterstop is connected, no breaks can be left in the middle, and the parallel lap method is adopted. After pouring the concrete, it can be pressed on the surface or inlaid. Waterstop construction methods are relatively diverse, including steel bar fixing method, lead wire and template fixing method, special fixture fixing method, etc. During the construction, the water stop belt must be fixed to avoid displacement during the subsequent construction process. At the same time, attention should be paid to the long construction time and the long exposure time in the open air to prevent rain.

4.The advantages and disadvantages of the water stop strip and the water stop belt.

The biggest advantage of the water stop strip is that it is cheap and convenient to use. The disadvantage is that the water stop effect is not as good as the water stop strip. The waterproof performance of the waterstop is better, and it has good elasticity. However, the waterstop also has some disadvantages, that is, it is easy to be punctured by sharp stones or steel bars in the concrete, and because the waterstop is relatively soft, the upper and lower widths are not easy to control, which is not very convenient during the construction process.