Concrete Rubber Waterstop: Ensuring the Integrity of Concrete Structures

Concrete is a widely used construction material due to its strength and durability. However, even the strongest concrete structures are susceptible to water penetration, which can compromise their integrity over time. To solve this problem, rubber waterstops have become an important part of concrete construction. These waterstops are designed to effectively prevent water from passing through concrete joints, ensuring the long-term stability and durability of the structure.

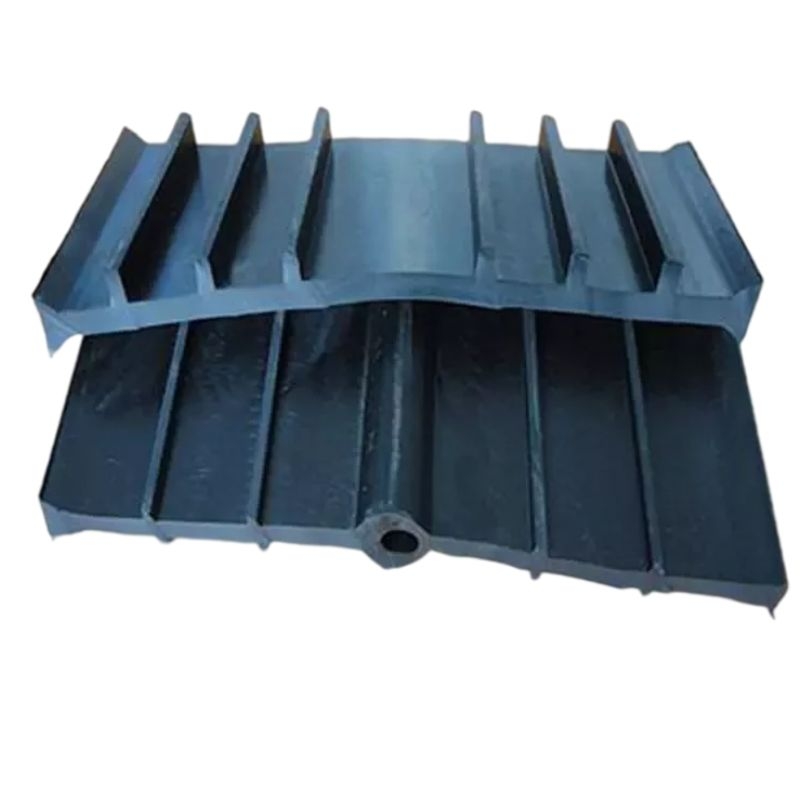

Concrete waterstops play a vital role in preventing water from seeping through expansion joints and construction joints and infiltrating concrete structures. These waterstops are typically made from high-quality rubber materials such as natural rubber, synthetic rubber, or a combination of both. Rubber’s flexibility and elasticity make it an ideal material for forming a waterproof barrier in concrete joints, effectively preventing water from entering or leaving the structure.

One of the main benefits of using rubber waterstops in concrete construction is their ability to accommodate movement and deformation within the structure. When concrete expands and contracts due to temperature changes or external forces, joints and penetrations can also move. Rubber waterstops are designed to flex and accommodate these movements, maintaining a seal and preventing water from seeping into the concrete. This flexibility is critical to ensuring the long-term performance of a structure, especially in environments where temperature changes and structural movement are common.

In addition to flexibility, rubber waterstops offer excellent resistance to chemical and environmental degradation. Concrete structures are frequently exposed to harsh environmental conditions, including exposure to chemicals, UV radiation, and weathering. Rubber waterstops are designed to withstand these challenges, ensuring the integrity of concrete joints remains intact throughout the life of the structure. This resistance to degradation is critical to maintaining waterstop effectiveness and preventing water-related concrete damage.

Installing rubber waterstops in concrete structures is a critical step in ensuring their long-term performance. Proper installation techniques, including the use of compatible adhesives and sealants, are critical to creating a watertight seal. Additionally, selecting the appropriate waterstop profile and size based on specific joint or penetration requirements is critical to achieving optimal performance. Working with an experienced professional who understands the intricacies of waterstop installation is critical to ensuring the effectiveness of your waterstop system.

The importance of rubber waterstops to concrete structures cannot be overstated. By effectively preventing water penetration, these important ingredients help increase the overall durability and longevity of concrete structures. Whether in a dam, tunnel, basement or other concrete structure, the use of rubber waterstops is critical to mitigating the risks associated with water damage and ensuring the long-term integrity of the concrete. As the construction industry continues to prioritize the longevity and performance of concrete structures, rubber waterstops remain indispensable in addressing water-related challenges.